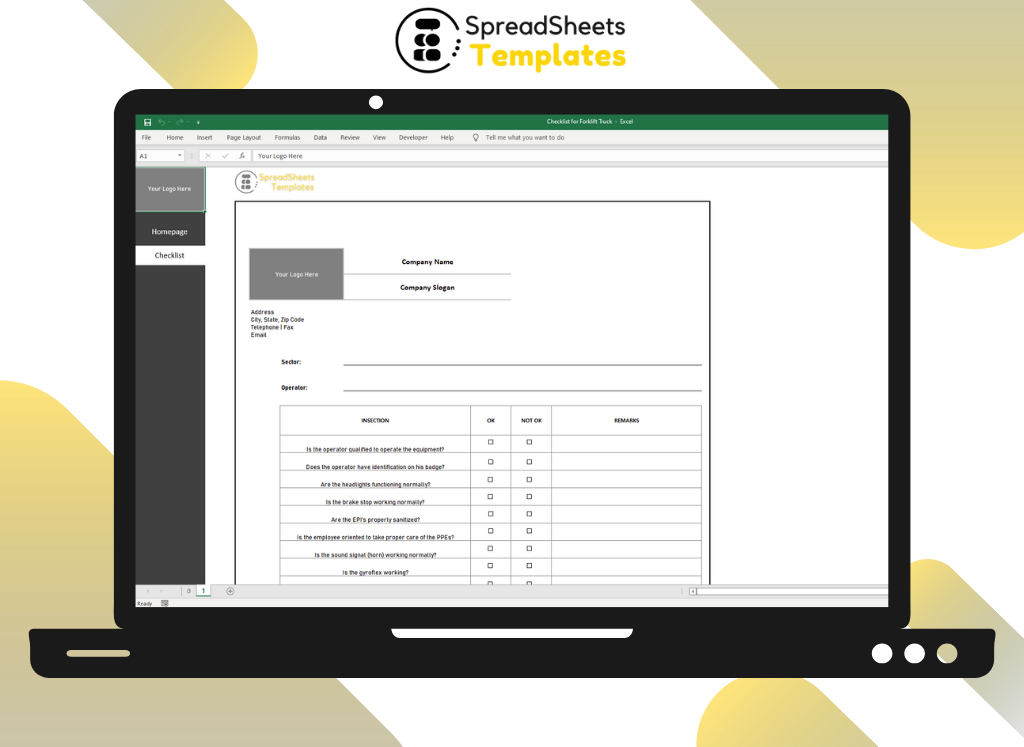

Checklist for Forklift Truck Worksheet Leave a comment

Ensuring Safety and Efficiency

Introduction

Welcome to this comprehensive guide on the checklist for forklift truck worksheet. Forklifts are essential equipment in various industries, providing invaluable support in material handling and logistics. However, operating forklifts involves inherent risks that need to be managed effectively. A checklist for forklift truck worksheet serves as a vital tool for ensuring safety, compliance, and operational efficiency.

Checklist for Forklift Truck Worksheet: What You Need to Know

To maintain safety standards and streamline forklift operations, it is crucial to have a checklist for forklift truck worksheet. This checklist outlines the key steps and tasks to be completed before, during, and after using a forklift. By following this checklist, operators can minimize the risk of accidents, identify potential hazards, and ensure the optimal functioning of the forklift.

Why is the Checklist for Forklift Truck Worksheet Important?

The checklist for forklift truck worksheet plays a critical role in promoting safety and efficiency in forklift operations. It serves as a comprehensive guide that covers all the essential aspects of forklift operation, including pre-operation checks, maintenance procedures, and emergency protocols. By adhering to the checklist, operators can:

- Ensure Compliance: Compliance with safety regulations and guidelines is essential for any organization. The checklist ensures that all necessary safety protocols are followed, reducing the risk of accidents and avoiding potential penalties.

- Minimize Accidents: Forklift accidents can result in serious injuries or even fatalities. The checklist includes pre-operation checks that help identify any potential issues or hazards, allowing operators to address them before starting work.

- Optimize Efficiency: A well-maintained forklift operates more efficiently, leading to increased productivity. The checklist includes maintenance tasks to keep the forklift in optimal condition, minimizing downtime and maximizing operational efficiency.

- Extend Forklift Lifespan: Regular maintenance and inspections outlined in the checklist help identify and address any mechanical or operational issues promptly. This proactive approach extends the lifespan of the forklift, saving costs associated with frequent repairs or replacements.

- Enhance Operator Awareness: The checklist prompts operators to be more vigilant about safety measures and best practices. By regularly reviewing the checklist, operators stay updated on the latest safety protocols and are more likely to adhere to them.

Checklist for Forklift Truck Worksheet: Pre-Operation Checks

Before operating a forklift, it is essential to conduct thorough pre-operation checks to ensure its safety and functionality. The following checklist items should be completed:

1. Visual Inspection

- Visually inspect the forklift for any visible damage, leaks, or loose parts.

- Check the condition of tires, including tread depth and inflation.

- Verify that warning lights, horns, and other safety features are functional.

2. Fluid Levels

- Check the fuel, oil, and coolant levels as per the manufacturer’s specifications.

- Top up fluids if necessary, ensuring they are within the recommended ranges.

3. Battery and Charging System

- Inspect the battery for corrosion or damage.

- Ensure the battery is adequately charged and the charging system is working correctly.

4. Controls and Instruments

- Test all controls, including the steering, brakes, and lifting mechanisms.

- Verify the accuracy of instruments, such as the gauges and indicators.

5. Forks and Attachments

- Examine the forks for any cracks, bends, or wear.

- Ensure that attachments are securely fastened and in good working condition.

6. Safety Devices

- Test all safety devices, including seat belts and overhead guards.

- Verify the functionality of lights, alarms, and other warning systems.

7. Documentation

- Check for the presence of the operator’s manual and other necessary documentation.

- Ensure that the forklift is properly labeled with load capacity information.

By diligently completing these pre-operation checks, operators can identify any potential issues or risks and take appropriate action before starting their work.

Checklist for Forklift Truck Worksheet: Operational Safety Measures

Operating a forklift safely requires adherence to certain operational safety measures. The following checklist items should be considered during forklift operation:

1. Operator Training and Certification

- Ensure all forklift operators have received proper training and certification.

- Regularly review training programs to keep operators up to date with the latest safety practices.

2. Load Handling and Stability

- Follow proper load handling techniques, including centering the load, securing it with appropriate restraints, and avoiding overloading.

- Maintain a low center of gravity by keeping the load as close to the ground as possible.

3. Speed and Maneuvering

- Operate the forklift at a safe and controlled speed, considering the load, surface conditions, and surrounding environment.

- Avoid abrupt turns, sudden stops, and excessive speed to prevent tipping or losing control.

4. Pedestrian Awareness

- Be aware of pedestrians and maintain a safe distance from them.

- Use horns, signals, or other warning systems to alert pedestrians of the forklift’s presence.

5. Elevated Work

- Follow proper procedures for working at heights, such as using elevated platforms or cages.

- Ensure the forklift is stable and the load is properly secured before lifting it to an elevated position.

6. Refueling and Recharging

- Adhere to proper refueling or recharging procedures to prevent accidents, such as fires or explosions.

- Follow the manufacturer’s instructions regarding fuel types and storage requirements.

By incorporating these operational safety measures into their daily routine, forklift operators can significantly reduce the risk of accidents and promote a safer working environment.

Checklist for Forklift Truck Worksheet: Maintenance and Servicing

Regular maintenance and servicing are essential to keep forklifts in optimal condition. The following checklist items should be included in a routine maintenance plan:

1. Daily Inspections

- Perform daily inspections to check for any visible damage, leaks, or signs of wear.

- Address any issues promptly or report them to the appropriate maintenance personnel.

2. Scheduled Maintenance

- Follow the manufacturer’s recommended maintenance schedule for routine servicing.

- This includes tasks such as oil changes, filter replacements, and lubrication.

3. Battery Maintenance

- Monitor and maintain the battery according to the manufacturer’s instructions.

- This may include cleaning terminals, checking electrolyte levels, and equalizing charges.

4. Tire Maintenance

- Regularly inspect tires for wear, damage, or punctures.

- Rotate tires as necessary to ensure even wear and optimal performance.

5. Forks and Attachments

- Inspect forks and attachments for wear, cracks, or other damage.

- Repair or replace any components that are no longer safe or functional.

6. Record Keeping

- Maintain a detailed record of all maintenance activities, including inspections, repairs, and part replacements.

- This record can help identify trends, track costs, and ensure compliance with maintenance schedules.

By following a comprehensive maintenance plan and regularly checking and servicing the forklift, organizations can maximize its lifespan, reduce the risk of breakdowns, and ensure safe and efficient operations.

Frequently Asked Questions (FAQs)

1. What is the purpose of a forklift truck worksheet?

A forklift truck worksheet serves as a guide to ensure the safe and efficient operation of forklifts. It outlines pre-operation checks, operational safety measures, and maintenance tasks to be performed, minimizing the risk of accidents and optimizing forklift performance.

2. How often should forklift operators conduct pre-operation checks?

Forklift operators should conduct pre-operation checks before each shift or whenever there is a change in operators. These checks help identify any potential issues or hazards that may affect the safe operation of the forklift.

3. Can forklift operators perform maintenance tasks themselves?

Operators can perform basic maintenance tasks, such as visual inspections and checking fluid levels. However, more complex maintenance tasks should be handled by trained technicians or maintenance personnel to ensure proper expertise and adherence to manufacturer guidelines.

4. What should operators do if they identify a safety issue during the pre-operation check?

If operators identify a safety issue during the pre-operation check, they should immediately report it to the appropriate maintenance personnel or supervisor. The forklift should not be used until the issue is resolved to ensure the safety of the operator and others in the vicinity.

5. Is operator training and certification necessary for forklift operation?

Yes, operator training and certification are essential for safe forklift operation. Proper training ensures operators are aware of the safety protocols, operational techniques, and potential hazards associated with forklifts. Certification provides evidence of competence and compliance with regulatory requirements.

6. How often should forklifts undergo maintenance servicing?

The frequency of maintenance servicing depends on several factors, including the forklift’s usage, operating conditions, and manufacturer recommendations. Generally, routine maintenance servicing should be scheduled at regular intervals, such as every 250 hours of operation or quarterly, to ensure optimal performance and safety.

Conclusion

In conclusion, a checklist for forklift truck worksheet is a valuable tool for maintaining safety and efficiency in forklift operations. By following the checklist’s guidelines, organizations can ensure compliance, minimize accidents, optimize efficiency, and extend the lifespan of their forklifts. Regular pre-operation checks, adherence to operational safety measures, and a comprehensive maintenance plan are vital for creating a safe working environment and maximizing the benefits of forklift usage.

Remember, safety should always be the top priority when operating a forklift. By integrating the checklist for forklift truck worksheet into your operational procedures, you can mitigate risks, protect your workforce, and enhance productivity.